Arizona Painting Company is proud to be one of the few companies in Arizona to offer Electrostatic Painting.

There are huge advantages that come with the electrostatic painting process. The finish is exceptionally smooth and even, it last two times longer than other painting methods and it is faster and more efficient than other methods. Electrostatic painting is the perfect answer for commercial painting and for creating a factory perfect finish on most any metal surface.

Applications for Electrostatic Painting

Commercial buildings, industrial facilities, schools, apartments and homeowner associations are typical benefactors of electrostatic painting because of the many metal components in both their interior and external areas. Parks and athletic facilities also have significant amounts of metal finishing which can utilize this superior painting application. Below is a list of just some of the applications for electrostatic painting:

- Metal doors and frames

- Metal railing

- Lockers

- Metal fencing and gates

- Metal playground equipment

- Metal bleachers

- Spiral stairs

- Utility fixtures

- Structural components

- Decorative metal

- Metal sculptures

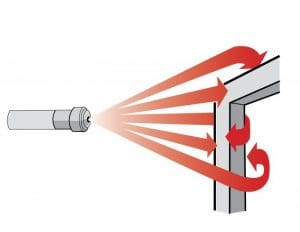

How Electrostatic Painting Works

‘

Reduced Paint Time, Reduces Cost

With electrostatic painting the amount of masking needed to protect adjacent areas is usually greatly minimized, but still may be needed to account for any minimal overspray. The time required to paint surfaces with an electrostatic application is greatly reduced. One pass rather than three or four is all that is generally needed. Fences and stair railing can often be done with an application from one side, not both. Less labor hours means reduced cost to the customer. The durable finish often last two times longer, meaning paint maintenance costs are lower due to less frequent painting.

Superior Finish

The fine spray and the magnetic draw of the paint to the metal creates an extremely smooth, even finish to the metal on which it is applied. Drips and brush strokes are eliminated. It is as close to a factory finish paint coat as can be achieved. It covers most old paint without an issue and adheres well, as long as the existing paint is well adhered to the metal. Our team always checks for issues related to previous paint applications and properly prep the surface prior to application to achieve the best results possible.

Electrostatic Painting FAQs

Q: What types of surfaces are best for electrostatic painting?

A: Electrostatic painting works best on metal and conductive surfaces, including railings, doors, door frames, lockers, elevators, office furniture, fencing, and equipment. It’s commonly used in commercial, industrial, and institutional settings.

Q: Is electrostatic painting durable?

A: Yes. When applied correctly, electrostatic painting creates a strong, long-lasting finish that resists chipping, peeling, and wear. It’s ideal for high-traffic environments where durability and appearance matter.

Q: Can electrostatic painting be done in occupied buildings?

A: In most cases, yes. Electrostatic painting produces minimal overspray and disruption, making it well-suited for offices, schools, healthcare facilities, and multi-tenant buildings. Projects can often be completed during off-hours to reduce impact.

Q: How is electrostatic painting different from traditional spray painting?

A: Unlike traditional spray painting, electrostatic painting allows paint to wrap around surfaces, reducing waste and delivering a more even finish. It’s faster, cleaner, and more precise—especially for complex metal surfaces.

Q: Is electrostatic painting cost-effective?

A: Electrostatic painting is often more cost-effective than replacement or traditional repainting, especially for metal fixtures and equipment. Faster application times and reduced material waste help keep project costs efficient.

Our Reviews